Chemical Safety and Handling Hazardous Substances: A Comprehensive Guide

In today’s world, chemicals play an integral role in various industries, from manufacturing and agriculture to healthcare and research. While chemicals provide numerous benefits, they also pose potential hazards if not handled properly. Understanding and implementing proper chemical safety practices is crucial to protect workers, the environment, and the public from harm.

Identifying Hazardous Substances

The first step towards ensuring chemical safety is to identify hazardous substances. Hazardous substances are those that can cause harm to human health or the environment. They can be classified based on their physical, chemical, and toxicological properties. Some common examples of hazardous substances include:

-

Flammable substances: These substances can easily ignite and cause fires or explosions. Examples include gasoline, propane, and ethanol.

-

Toxic substances: These substances can cause adverse health effects through ingestion, inhalation, or skin contact. Examples include lead, mercury, and pesticides.

-

Corrosive substances: These substances can damage materials and tissues by chemical reaction. Examples include acids, bases, and alkalis.

-

Radioactive substances: These substances emit radiation that can damage cells and cause cancer. Examples include uranium, plutonium, and radium.

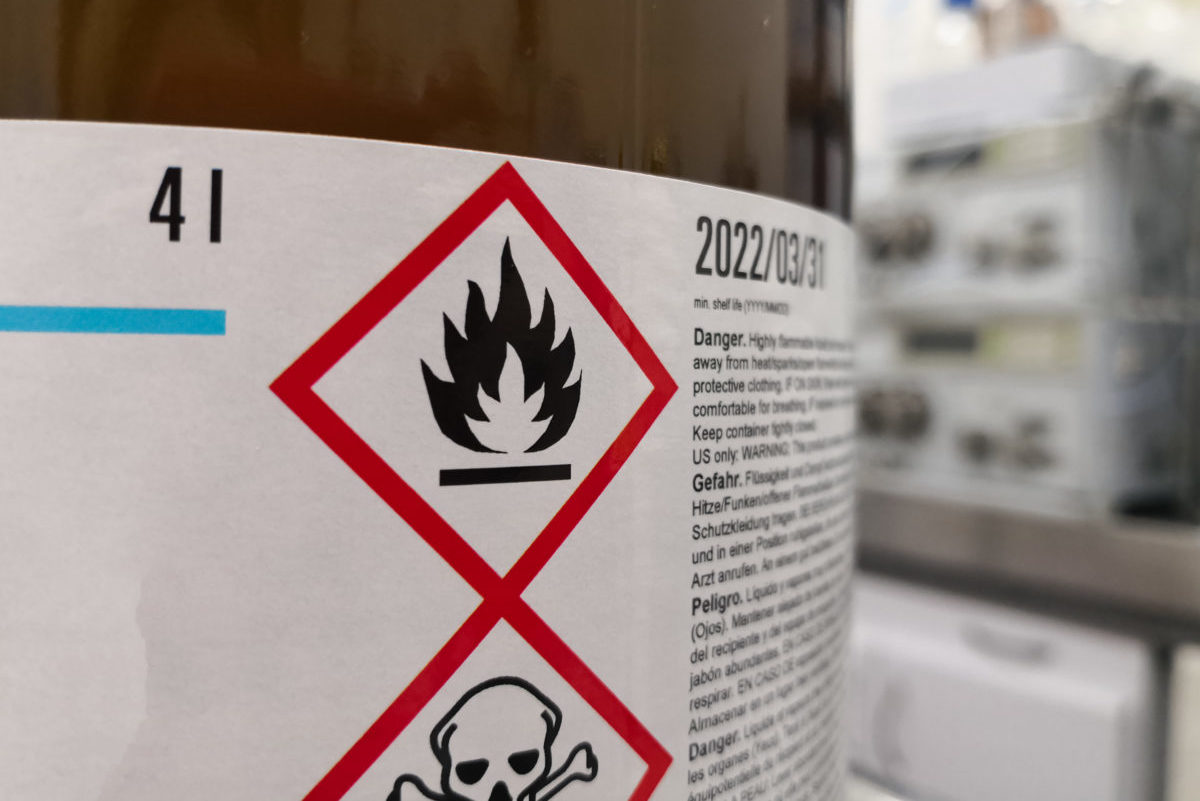

Hazard Communication

Hazard communication is the process of conveying information about hazardous substances to workers. This information helps workers understand the hazards associated with the substances they work with and take appropriate precautions to protect themselves.

The most common method of hazard communication is through labels and safety data sheets (SDS). Labels provide basic information about the substance, such as its name, hazard class, and pictograms indicating the types of hazards. SDSs provide more detailed information about the substance’s properties, hazards, and emergency procedures.

Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is a critical component of chemical safety. PPE is specialized equipment designed to protect workers from exposure to hazardous substances. The type of PPE required depends on the specific hazards of the substance being used.

Common types of PPE include:

-

Respiratory protection: Respirators protect workers from inhaling hazardous fumes, gases, or dust.

-

Hand protection: Gloves protect workers’ hands from contact with hazardous substances.

-

Eye protection: Safety glasses or goggles protect workers’ eyes from splashes or airborne particles.

-

Skin protection: Coveralls, aprons, and boots protect workers’ skin from contact with hazardous substances.

Engineering Controls

Engineering controls are physical measures designed to reduce or eliminate exposure to hazardous substances. They are often considered the most effective way to control hazards.

Common types of engineering controls include:

-

Ventilation: Ventilation systems remove hazardous fumes or gases from the workplace.

-

Local exhaust systems: Local exhaust systems remove hazardous substances from the source of generation.

-

Isolation: Isolation techniques separate workers from hazardous substances, such as physical barriers or robotic equipment.

Emergency Procedures

Despite careful planning and implementation of safety measures, accidents can still happen. Having emergency procedures in place is essential to respond effectively to chemical spills, fires, or other emergencies.

Emergency procedures should include:

-

Emergency contact information: A list of emergency contacts, such as fire department, ambulance, and poison control center.

-

Evacuation plan: A plan for evacuating the workplace in case of a major emergency.

-

Spill cleanup procedures: Instructions for cleaning up chemical spills.

-

Fire suppression procedures: Instructions for using fire extinguishers and other firefighting equipment.

Global Safety Training: Your Partner in Chemical Safety

Global Safety Training is a provider of online safety training courses, including specialized courses on chemical safety and handling hazardous substances. Our comprehensive courses provide workers with the knowledge and skills they need to work safely with hazardous chemicals.

Our courses cover a wide range of topics, including:

-

Hazard identification and classification

-

Hazard communication

-

Personal protective equipment (PPE)

-

Engineering controls

-

Emergency procedures

Our online courses are convenient and accessible, allowing workers to learn at their own pace, from anywhere in the world. We also offer customized training solutions to meet the specific needs of your organization.

Chemical safety is a shared responsibility that requires the collaboration of employers, employees, and regulatory bodies. By understanding the hazards associated with hazardous substances, implementing appropriate safety measures, and providing comprehensive training, we can work together to prevent chemical accidents and protect the health and safety of workers, the environment, and the public.