As a business owner or manager, the safety of your employees is paramount. Not only is it a moral obligation, but it’s also essential for your business’s success. Workplace injuries and illnesses can lead to costly downtime, increased insurance premiums, and even legal repercussions. That’s why complying with OSHA regulations is so crucial.

The Occupational Safety and Health Administration (OSHA) is a federal agency tasked with ensuring safe and healthy working conditions for all American workers. They do this by developing and enforcing workplace safety and health standards. While there are numerous OSHA standards to be aware of, some violations consistently top the list year after year.

In this article, we’ll delve into the top 5 most frequently cited OSHA violations and provide practical tips on how to prevent them in your workplace. By understanding these common pitfalls and implementing proactive measures, you can create a safer environment for your employees and avoid costly OSHA citations.

1. Fall Protection

Falling from heights remains the leading cause of workplace fatalities in the construction industry and a significant hazard in other industries as well. That’s why it’s no surprise that Fall Protection violations top OSHA’s list year after year.

Common Fall Protection Violations:

- Lack of fall protection equipment (such as guardrails, harnesses, and lanyards)

- Improper use of fall protection equipment

- Working at unsafe heights without proper fall protection

- Failure to train employees on fall hazards and fall protection procedures

Preventing Fall Protection Violations:

- Conduct regular hazard assessments to identify fall hazards.

- Implement and enforce a fall protection plan that meets OSHA standards.

- Provide and maintain proper fall protection equipment for all employees who work at heights.

- Train employees on fall hazards, fall protection procedures, and proper equipment use.

- Inspect fall protection equipment regularly and ensure it is in good working condition.

2. Hazard Communication

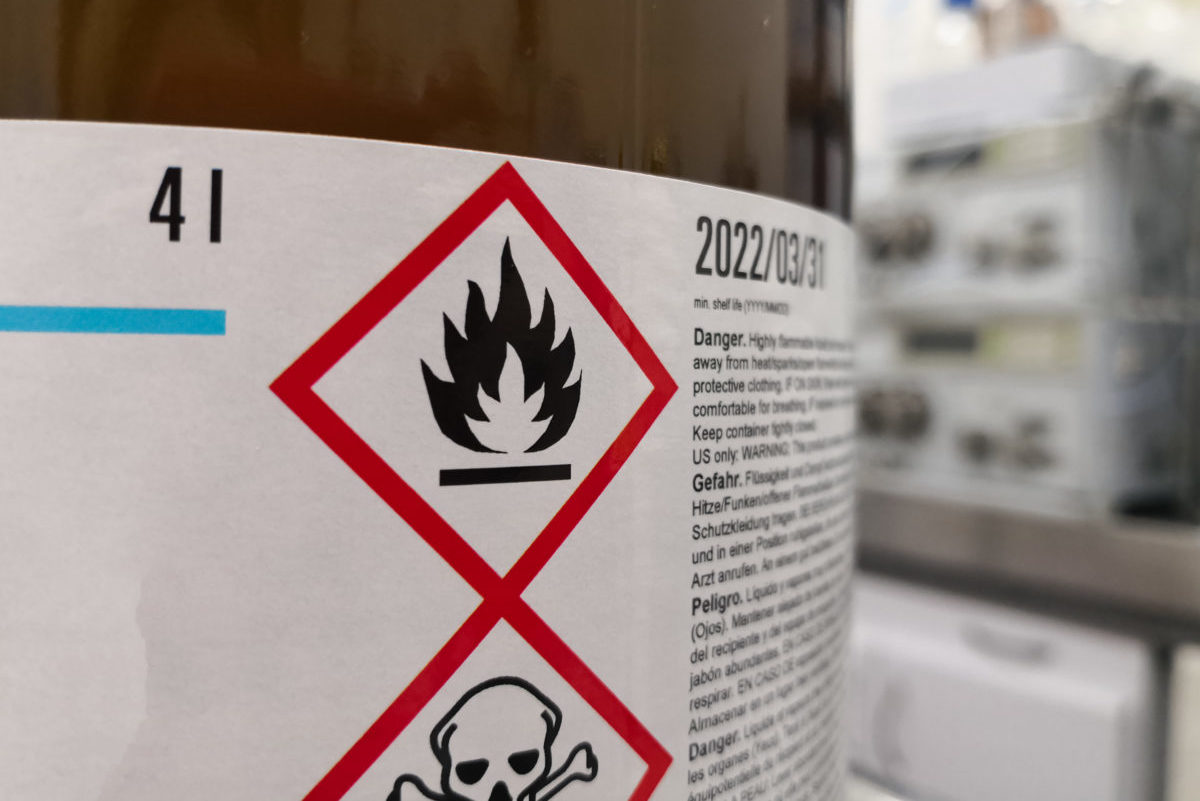

Hazard communication is crucial for ensuring employees understand the potential dangers associated with the chemicals and other hazardous materials they may encounter in the workplace. This standard also requires employers to provide training on how to handle and protect themselves from these hazards.

Common Hazard Communication Violations:

- Lack of Safety Data Sheets (SDSs) for hazardous materials

- Inadequate labeling of hazardous materials

- Failure to train employees on hazard communication procedures

Preventing Hazard Communication Violations:

- Maintain a complete inventory of all hazardous materials used in your workplace.

- Ensure all hazardous materials are properly labeled with relevant hazard information.

- Obtain and maintain SDSs for all hazardous materials and make them readily accessible to employees.

- Train employees on hazard communication procedures, including how to identify hazards, read SDSs, and use personal protective equipment (PPE).

3. Ladders

Ladders are a common tool used in various workplaces, but they can also be a source of serious injuries if not used safely. OSHA has specific standards for ladder use to prevent falls, slips, and other hazards.

Common Ladder Violations:

- Using the wrong type of ladder for the job

- Overextending ladders

- Placing ladders on uneven or unstable surfaces

- Failing to secure ladders properly

Preventing Ladder Violations:

- Choose the right ladder for the job, considering the height, weight capacity, and type of work being done.

- Inspect ladders before each use for damage or defects.

- Place ladders on firm, level ground and secure them properly.

- Do not overextend ladders beyond their rated capacity.

- Train employees on safe ladder use practices.

4. Scaffolding

Scaffolding provides temporary platforms for workers to access higher areas, but it can also be a source of danger if not erected and used properly. OSHA has specific standards for the construction, use, and inspection of scaffolding.

Common Scaffolding Violations:

- Inadequate or missing guardrails and toe boards

- Overloading scaffolds beyond their weight capacity

- Failing to properly secure scaffolding planks and braces

- Lack of fall protection for workers on scaffolds

Preventing Scaffolding Violations:

- Have qualified personnel erect and inspect scaffolding before each use.

- Ensure scaffolding meets OSHA standards for load capacity, guardrails, and fall protection.

- Train employees on safe scaffolding use practices.

- Regularly inspect scaffolding for damage or defects and correct any issues immediately.

5. Powered Industrial Trucks (Forklifts)

Forklifts and other powered industrial trucks are essential equipment in many workplaces, but they can also be dangerous if operated incorrectly. OSHA has specific standards for forklift training, operation, and maintenance.

Common Powered Industrial Truck Violations:

- Operating forklifts without proper training or certification

- Overloading forklifts beyond their capacity

- Driving forklifts at unsafe speeds

- Lack of proper maintenance of forklifts

Preventing Powered Industrial Truck Violations:

- Ensure all forklift operators are properly trained and certified.

- Implement and enforce safe operating procedures for forklifts.

- Conduct regular inspections of forklifts to ensure they are in safe working condition.

- Require forklift operators to wear appropriate personal protective equipment (PPE).

By understanding and addressing these top 5 OSHA violations, you can create a safer work environment for your employees, prevent costly citations, and ensure the continued success of your business. Remember, workplace safety is an ongoing process, and continuous vigilance is key to preventing accidents and injuries.